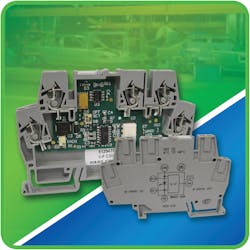

Wago DIN-rail Voltage-to-Frequency Converters

Wago Corp.’s two new 0–10VDC 859 Series Voltage-to-Frequency Converters provide output frequencies of 0–1.5KHz or 0–25KHz for pulse generation. Developed by Wago’s Custom Products Division, the DIN-rail mount Voltage-to-Frequency Converters (VFCs) simplify simulators by replacing standalone frequency generators, rotating equipment and associated cabling. This enables machine-builders to design more cost-effective simulators for industry and transportation, e.g., QA or performance testing.

Serving industrial applications, such as variable frequency drives, Wago’s VFCs mimic motor encoders to generate pulse inputs for controlling lighting or machine speed. Isolated VFCs are also available for excessively noisy environments or applications with high potential differences between machinery. Within vehicle/non-automotive transport simulators, the VFCs pulsate to mimic wheel speed for tachometer and speedometer readings — no costly subassemblies with rotating tires or cabling. Beyond drivetrain development, streamlined simulators can help develop or economize driving skills.

Manufactured at Wago’s Wisconsin headquarters, the two 859 Series VFCs can be factory-tuned to a customer-specified frequency within three ranges: 0–1.0KHz, 0–1.5KHz or 0–25KHz. Based on WAGO’s industry-proven 859 Series Relays, the VFCs employ Cage Clamp Spring Pressure for connections that resist vibrations and current-induced temperature cycling. Operating temperatures range between 0 degrees C to +40 degrees C.