Make Digitalization Part of Your Rail and Transit Strategy

The world’s population is expected to rise to 10 billion people by 2050. The combination of a growing population and increased urbanization is placing a considerable strain on infrastructure. Rail and transit networks, in tandem with roads and bridges, will be most affected because they are critical to mobility in cities and across the nation.

However, the latest innovations in linear analytics can help maintain infrastructure assets and optimize maintenance decisions. It can also accelerate the return on investment in technology by leveraging rapidly deployed analytical and decision support tools that reduce risk and improve service, safety and long-term reliability.

The New Normal

The effect that COVID-19 has on daily life can not be ignored. However, it has also created new opportunities and can be a business driver for change for the better. For many, working from home will become part of a better work-life balance, so communication and collaboration tools like Microsoft Teams, Zoom and Bentley’s ProjectWise 365 are increasingly important.

“Now is the time to start reimagining our industry and how organizations can emerge in the next normal from a position of strength,” said McKinsey & Company’s article How construction can emerge stronger after coronavirus from May 2020. The article advocates for increased digitization, remote working and a greater reliance on building information modelling (BIM)—advancing to include 4D and 5D simulation to re-plan and reoptimize project schedules. The report also identifies digital twin solutions for providing current and ongoing feedback, as well as insight into the decision processes. The article authors believe that the case for digital tools proven to increase productivity will become even stronger, including increased use of off-site construction, where working in controlled environments makes it easier to keep people safe and improve quality.

These findings mirror the belief at Bentley Systems that advanced technologies can help users deliver improved business outcomes across the lifecycle of infrastructure assets. This improvement might be through smarter decisions that help target project investment, optimize design, save money or enhance safety. The bottom line, however, is that the decisions made today will impact lives tomorrow.

Data-driven Decisions with Digital Twins

Change is not unfamiliar to the industry having seen the evolution of servers to cloud-based storage that support digital strategy. There has also been a shift from 2D to CAD and now to 5D, where BIM standards and processes deliver productivity and quality improvements.

Moving beyond BIM—fueled by the increasing amounts of data that is collected, created and consumed in day-to-day tasks, and the volume of connected devices delivering so-called big data and the Internet of Things (IoT)— more decisions are made with the insight gained directly from data. It is why Bentley believes that infrastructure digital twins will be the next big digital disruption in the industry.

Digital twins are already enabling organizations to visually immerse their teams in the decision-making process and run advanced analytics to predict and produce different outcomes, as well as track and manage the change that can be seen across the delivery of projects and throughout an asset’s operational life.

Bentley’s iTwin technology enables the federation of data and deliverables from engineering and design, with live or near real-time data streams from IoT-connected devices in operations to connect the physical asset in the real world with its digital counterpart: its digital twin.

ASCE: America’s Infrastructure Report Card

Every four years, the American Society of Civil Engineers (ASCE) publishes a report on America’s infrastructure. The 2021 Report Card shows that the U.S. is not investing in “the backbone of our economy.” It costs every American household US$3,300 a year. When multiplied by the roughly 132 million U.S. households predicted to exist at the end of 2021, it has a significant effect on the nation’s economy.

The report scored rail and transit with grades B and D, respectively. The lack of federal support has led to the current rail state of good repair (SGR) backlog of US$45.2 billion.

With transit, the situation is worse. Currently, there is a US$176 billion transit SGR backlog, nearly four times as much as rail, with the deficit expected to exceed US$250 billion by 2029. Meanwhile, transit ridership is declining—a trend further compounded by COVID-19, which has seen some agencies experience a 70 percent drop in passenger numbers.

Failure to address the shortfall for passenger rail and transit only exacerbates the existing challenge of ridership decline, creating a downward spiral—unless a change is made and the future is reimagined.

SMRT Trains: The Future of Rail and Transit

There is clear evidence within projects of Bentley users around the world that going digital, including the use of digital twins, is already enabling organizations to reimagine the future of rail and transit.

One such organization is SMRT Trains (SMRT). The first rail operator in Singapore, it operates and maintains more than 282 kilometers (175.2 miles) of track. With an average daily ridership of more than two million people in 2020, SMRT needed a method to keep the tracks in good condition to avoid delays.

System reliability is measured using mean kilometers between failure (MKBF). To improve reliability, SMRT set a target of one million MKBF for all its lines—the equivalent of traveling over the entire network thousands of times before seeing a service delay of five minutes or more. However, SMRT relied on intensive, time-consuming and manual maintenance planning using tens of millions of data points per year across separate data silos.

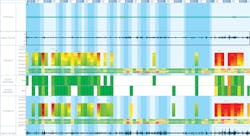

To enable engineers to make optimized decisions using all relevant data, SMRT used Bentley’s linear analytics as the basis of its predictive decision support system (PDSS). With the PDSS, engineers can visualize multiple datasets in one view to see different track subsystems, enabling more in-depth engineering analysis. The system automatically pulled SMRT’s existing data, allowing engineers to review the events leading to the current asset condition.

As of August 2019, SMRT achieved its one million MKBF target. Data correlation is twice as fast and with easy access to data, it has significantly streamlined multiple analyses. With prioritization implementation, SMRT cut hundreds of manual planning hours and saved about 20 maintenance train deployments annually. Engineers also have a better idea of work conditions, allowing improved preparation in advance and saving time on the site.

Reimagine the New Normal

As the operator of a large and busy network, SMRT is using technology to work smarter and move forward to continuously improve its maintenance efficiency and effectiveness. But smaller networks—such as metros, shortlines and mass transit—face similar challenges, especially when it comes to ensuring the continued safe and reliable running of their networks. So, how can these organizations unlock the potential of their data?

SMRT’s experience serves as an example for other metros looking to a cloud-based solution that includes pre-configured data import tools and linear analytics. Through a rapidly deployed solution, such as AssetWise Rail Condition Analytics, agencies can work smarter and develop proactive strategies using automated key condition score reporting and visibility into past maintenance activities. Engineers can predict and validate future decisions that help improve service, safety and reliability. These latest innovations in linear analytics let rail and transit owner-operators increase the value of their track maintenance activities, resources and budget by completing the right work, in the right place, at the right time to create a safer network for a better tomorrow.

----------------------

Narinder Manku, is Bentley Systems' solution marketing manager for Rail Asset Performance.

About the Author