Six ways to ensure your transition to electric buses is a success

Only two percent of buses in the United States are zero-emission or battery-powered. Changing that is central to meeting the nation’s goal of reducing greenhouse gas emissions by 50 to 52 percent below 2005 levels by 2030.

Accordingly, on Aug. 5, 2021, President Joe Biden signed an executive order setting a target for zero-emission vehicles to account for 50 percent of all U.S. vehicle sales by 2030. 5 The Senate’s recently passed bipartisan infrastructure bill reinforces this goal with $7.5 billion for electric buses, $7.5 billion for charging stations and $6 billion for battery supply chain and battery-pack manufacturing. Zero-emission bus fleets are looking increasingly attainable for agencies, some of which aim to be 100 percent electric by 2040. Agencies that already have all-electric fleets, like Antelope Valley Transit Authority (AVTA) in California, could receive support for fleet maintenance or expansion.

Investment in electric buses and chargers is key to reducing emissions, and funding from various grant programs such as the Low or No Emissions Program will help overcome the purchase costs. But the successful roll-out of electric vehicles is more complicated than coming up with capital or simply putting vehicles on the road. Packaged in with electric buses are complex specs poised to disrupt existing schedules and routes. Policies that support the ongoing operations of electric vehicles are just as critical to ensure widespread adoption and success, as is the digital transformation of scheduling processes.

As agencies transition their fleet, they should ensure that their operations team understands and accounts for a host of new electric vehicle parameters, including:

- Electricity costs: Charging is one particularly multi-dimensional challenge for current schedules. As opposed to diesel, electricity costs fluctuate throughout the day and more dramatically than diesel or natural gas. Timing purchases to periods of reduced energy demand, when prices are lower, is key to minimizing energy costs, and thus also operational costs. Collaborate with public utilities companies early on. In many cases, overnight bus recharging can support load balancing. Energy companies may be charged higher rates for excess storage during that time of day and may welcome the partnership. This is more complex than simply pulling up to the pump.

- Charging station location and type: The availability and type of charging infrastructure also fits into the equation. Some gas stations are piloting EV chargers to future-proof their businesses, but others cannot justify the $100,000 cost for a single charger, given the small share of EVs currently on the road. The amount of en-route chargers in the area will determine whether drivers can take advantage of opportunity charging, or if buses must return to the depot for each charge. Charger location will also impact the charger type. Fast chargers that allow buses to quickly charge in layover locations are situated in high-density areas. Slow chargers that charge buses at a slower rate, usually overnight, are often located at the depot. Charging locations must be aligned with charging needs of the entire fleet and will also determine the number and duration of deadhead trips required to reach chargers, thus impacting the amount of services offered. Agencies and operators should decide which charging strategy -- quick or slow -- best serves their operation.

- Coordinating charging times and availability: It only takes several minutes to fill up a diesel bus once per day and then travel 400 miles at a fixed cost. An electric bus takes one to six hours to charge one to three times per day, giving it a range of 70-250 miles with variable costs. Charging too many electric buses simultaneously could create an EV shortage that forces agencies to use diesel buses to fill the gap. On the other hand, suboptimal charging can decrease battery range and thus increase the vehicle count required to operate a timetable. This raises operational costs and takes away vehicle resources that could create an extra line or a new route in a transit desert. Effectively coordinating when, where and for how long charging occurs is key to delivering quality services and minimizing vehicle resources. This becomes exponentially complicated as EV fleet size increases.

- Weather: Weather impacts energy availability, cost and battery performance. Extreme heat or cold, as well as the heating and cooling systems needed to keep passengers comfortable, can drain batteries and exacerbate range limitations. This sometimes prevents buses from completing shifts, since EVs cover 20 percent fewer miles in cold weather. Even with extra charging, electric buses have less range during extreme temperatures.

- Typography: Cities with hilly terrain may see their electric buses struggle or fail to traverse inclines, causing delays or canceled services. Extra weight from overcrowding can strain battery power and speed. Driver behavior and road conditions also impact battery performance, as they do with diesel buses. Batteries degrade over time, meaning over an electric bus’s lifetime, their charging schedule or routes will change. And of course, some battery ranges are lower in reality than initially advertised.

- Agility and speed (planning for the moment in real-time): In a traditional fleet, one challenge is to connect all trips with the fewest buses possible, while minimizing deadhead cost. Optimizing this scenario is simple in comparison to an EV scenario, which must consider not only deadheads, but also charging location (en-route or depot), energy costs (aiming for low-demand, low-cost slots), charger availability, charge duration (quick charging versus long charging) and seasonal battery range, among others.

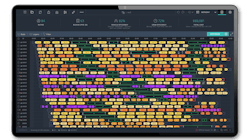

The web of possible outcomes for the EV scenario is expansive. Arriving at the best solution could take days using legacy software and weeks using manual methods, both of which may produce errors that render the ‘solution’ ineffective. The pandemic proved that keeping pace with (daily) changes is critical to delivering quality services. If weather or energy costs shift overnight, or within hours, as they do in certain regions, schedulers will need to understand almost immediately how that impacts range and quickly adjust schedules in real time, not days later.

These new, complex EV parameters will challenge old, antiquated tools that cannot support modern requirements. Adopting more powerful, digital scheduling processes with algorithmic ability is crucial to effectively managing electric vehicles. And since the specific characteristics of each region and transit network mean there is no one-size-fits-all solution for the industry, digitalization plays a role in developing the custom strategies needed to manage EVs in a local context.

As fleets become increasingly electric, the industry must ensure it invests not only in the initial vehicle purchase and chargers, but also in the operating means to ensure success. Digital transformation through highly responsive scheduling and management software will enable schedulers to make better, faster decisions regarding complex EV parameters, optimize public transit resources and fluidly adjust to new challenges, all while making cities greener and passengers happier.

About the Author