CASE STUDY: Arcadis Hurontario Light Rail Project Design: "Global Resources - Local Mobility"

It is entirely possible that the Hurontario Light Rail Project in the greater Toronto area of Canada is the most digitally transformative project in the history of light-rail transit project design. The project included the most talented multi-disciplinary rail design teams from across the globe, a variety of the latest technological solutions and its management team was forced to overcome the unexpected challenges of a global pandemic.

Despite the delay on the design development due to the global pandemic circumstances affecting traveling conditions, face to face interactions and general working environments; The light-rail project design is now becoming reality thanks to a ground-breaking approach that leveraged the project management team’s commitment to digital transformation that would not allow challenges like global communication, accommodation of multiple time zones, differences in technology availability, evolving environmental sustainability goals and a worldwide pandemic slow them down.

HURONTARIO LIGHT RAIL PROJECT OVERVIEW

According to the project website, when in service, the 18-kilometer (11.2-mile) LRT line (which will be known as the Hazel McCallion Line) will bring a new, environmentally friendly and reliable method of transportation to a rapidly growing region. The new transit system will feature 18 stops and one station, travel through two urban growth centers and connect to major transit systems including GO Transit (Milton and Lakeshore West lines), the Mississauga Transitway, Brampton Transit, Züm and MiWay. The line will operate in its own dedicated lane ensuring a smooth, reliable and convenient ride along the region’s busiest street.

As Mississauga and Brampton expand with new residents, businesses and amenities, sustainable and reliable transit is considered to be vital to ensure quality of life for the area’s residents. The Hazel McCallion Line will operate with clean, electrically powered light-rail vehicles, producing near zero emissions. Not only does the LRT line get cars off the road, but it’s a more sustainable, environmentally conscious way to travel. The line is anticipated to be fully operational before the end of 2024.

PROJECT DESIGN TEAM CHALLENGE: PROJECT SCHEME COMPLEXITY

An initial challenge for the track/systems civil and environmental design team, which was led by Arcadis as part of the IBI and Construction Joint Venture (IBI/CJV) design team, was the complexity of the LRT plan itself. The existing infrastructure where the LRT line was planned had a multitude of constraints for the design team. There were property acquisition issues along the entire existing roadway where the line will be traveling, including space constraints for minimum required widths. The line will also traverse two different municipalities, each with their own approval processes.

The vertical clearance requirements were also constrained by multiple interfaces with high-voltage cables, requiring an additional level of coordination between the project sponsor and the power supply company to adjust track alignment where needed.Another initial obstacle was ensuring the team’s understanding of the local standards to which the line needed to be designed. According to UK-based Warren Gower, Arcadis Rail Systems Director and Professional Head of OCS, the global experts assembled for the project needed to familiarize themselves with a set of standards that, were quite different than that with which they were accustomed.

"Our team was familiar with the design standards and requirements from across the globe, but many needed to get up to speed on North American standards," said Gower. "These included AREMA and TCRP 155, the various project agreement (PA) clauses, as well as the Canadian scope of work comparable to other large infrastructure projects in the UK, for example."

PROJECT DESIGN TEAM CHALLENGE: MANAGING CHANGE AND AVOIDING PROJECT TEAM SILOS

The complexity of the multi-disciplinary team’s organization included the potential for a variety of silos to develop, too. The team included a cadre of firms and resources that resided in several different countries and time zones, including the Arcadis track/systems civil and environmental design teams in Canada, UK, India, North America, the Netherlands and Romania, as well as the Hitachi systems design team in Italy and France with whom the Arcadis team needed to coordinate.

"CJV employed the use of what we called 'interface managers' throughout the project to engage with other design team members to ensure we broke down these silos before they developed, managed changes as they occurred and matched-up the timing of the designs as best we possibly could," explained Gower.

For example, according to Fernando Romero, Arcadis senior track engineer, "Our track design team had to re-align the track to accommodate late-breaking adjustments from the systems design team. Not only do these changes impact the track alignment, but they also affect the roadway, landscape and other design disciplines. Despite this, we successfully delivered these re-alignments through close design integration and the use of a common data environment."

PROJECT DESIGN TEAM CHALLENGE: GLOBAL PANDEMIC

When the Hurontario LRT project initially kicked off, no one could have imagined the additional level of complexity that the COVID-19 pandemic would force upon the team— especially given that each country (and even each province or state in North America) reacted differently to reflect the individual local effects of the pandemic.

"At one point, we in the UK were completely free to go about business, but, at the same time there were trucking industry demonstrations in Canada that slowed down transportation and commerce activities which greatly affected our team there," said Gower. "The use of Microsoft Teams was critical to our mitigation efforts to the delay impacts originated in the challenges imposed by the global pandemic situation. At Arcadis, we were designed to work remotely well before the pandemic, so our flexible work environment allowed us to avoid a massive transition, therefore increasing our ability to mitigate the delay impacts created by the changing conditions during the global pandemic and it was easy for our global teams to carry-on working as normal, with adjustments as required by the new conditions under the traveling restrictions and limitations to face to face interactions."

ARCADIS DOES DIGITAL DIFFERENTLY

Arcadis Global Digital Transformation Lead Andrew Victory views digitization as a transport industry mega-trend.

"The main drivers of change in urban transport are sustainability and digitization," said Victory. "The world continues to tackle a pressing climate emergency, necessitating the use of proactive measures that create zero to minimal environmental impacts. At the same time, environmental sustainability and population health protection in the post-COVID-19 society require a constant optimization of the balance among transportation modalities. Technological advancement also demands the integration of digital assets into the transport sector."

The core of Arcadis' companywide digitization philosophy is the belief that the industry needs more enduring and timely mobility solutions—driven by technology—that will enable the company not just to survive but to thrive in the modern world. This philosophy was exhibited throughout the design of the Hurontario LRT project.

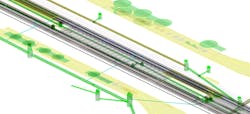

"The first thing we did differently was to transition to a nearly 100 percent 3D design using Bentley Systems’ OpenRail Designer solution for modeling, parametric design and its automated updating of the 3D model," said Gower. "The project benefited immediately from this transition because the 3D modelling of track slab and rails has been much quicker with minimal errors."

According to Ganapati Bhat, Arcadis BIM senior manager based in India, the parametric design capabilities of OpenRail Designer were crucial to the digital automation of the overall project.

"There is intelligence within the model's parametric cells, so if data is changed elsewhere in the digital environment, the cells will automatically change along with the whole design to accommodate the changes," noted Bhat.

OpenRail Designer's state-of-the-art solution was critical to Arcadis' track alignment and civil systems design. "OpenRail helped us overcome the complex challenge of designing the track alignment such that all adjacent infrastructure could be positioned to be clear of the Track Clearance Envelope (TCE)" said Romero. "Additionally, the land available for the Operations, Maintenance and Service Facility (OMSF) was very limited, so the technology played a critical role in designing and coordinating acceptable solutions that were integrated with other infrastructure elements, whilst ensuring compliance to the standards."

Another unique element of Arcadis' approach was the use of the University of Huddersfield in the United Kingdom to perform the wheel/rail interface simulations. According to Gower, "the university team performed simulations and produced wheel/rail interface reports that flagged up any issues that might occur with maintenance, track wear and at junctions with a lot of activity. This is a very specialized area that is critical so that our design teams could identify mitigation measures such as friction modifiers to make the track last longer and attend to whole life-cycle costs."

Another part of the Bentley Systems solution employed by the Arcadis and IBI/CJV team was its ProjectWise BIM collaboration software.

"ProjectWise is really the only Common Data Environment (CDE) tool we use," said Ben Green, Arcadis BIM manager. "It's baked into everything we do. So-called 'paper-based processes' would take forever, but ProjectWise gives us greater version control."

Green explained that if data are revised in ProjectWise, the engineers and project managers receive notifications that data may be outdated or require attention. This digital tool allows the team to investigate in real-time and accept any modifications across the globe.

"It allowed us to work seamlessly as a global company," added Green. "You don't even need to be connected to the same company server or network—it is that user-friendly."

Of course, the dedication to digitization helped partially mitigating the delay impacts as the world recovered from the effects of the pandemic. One example involved the systems cable ducting placed under the trackform.

"The original ducting was concrete, but due to the pandemic the materials needed for the original large PVC ductwork were difficult to obtain in Ontario. The client's shift to a multi-duct design (using high-density polyethylene or HDPE) that uses materials that are more readily available allowed us to modify our designs quite quickly using automated 3D design tools like OpenRail, too," recalled Bhat.

Another pandemic-related digitization process involved the required measurements of the rail line's noise and vibration levels in homes and other structures along the line. According to René de Vries, Arcadis senior vice president and environmental lead on this project, because of the health precautions taken due to the pandemic, the team could not collect noise levels in person inside residences.

"We used digital modeling, with the contracting authority's approval, to determine necessary mitigation measures required for Noise and Vibration." said de Vries.

DIGITAL TRANSFORMATION RESULTS IN MOBILITY REFORMATION FOR TORONTO AND ONTARIO

The City of Toronto is striving to be even more of a world class city than it already is, with CA$50 billion (US$38.01 billion) in construction either planned or underway, including the Hurontario LRT. To secure world-class city status, especially in the post-COVID-19 society, every project will need to include digitization and globalization.

"In order to accomplish this decades-long mission, the governments of Toronto and Ontario must connect communities with mobility solutions that are sustainable and move people from roads to rail," said de Vries. "As a leader in digital and with our Global Excellence Teams across 70 countries worldwide, Arcadis is the perfect partner for this project—largely because our mission is ‘Improving Quality of Life’ for the communities we serve and, of course, that includes Toronto."

"Arcadis' commitment to innovation and digitization has made it possible for us to use our global resources to develop a local solution for Toronto," added de Vries. "This project will reduce CO2 emissions, enhance lives and, hopefully, have a positive impact to reducing North America's car culture."

Sponsored By: