The Utah Transit Authority's (UTA) Jordan River Rail Service Center (JRRSC) is a light rail vehicle maintenance and storage facility constructed within an existing 200,000 square foot warehouse building purchased by UTA in 2007. UTA received a grant through the American Recovery and Reinvestment Act of 2009 for $24.6 and the total estimated cost of the renovations were approximately $50,302,000.

During the recent American Public Transportation Association recently held the Rail Conference and Roadeo in Salt Lake City, Utah, and the UTA offered a technical tour of the JRSSC.

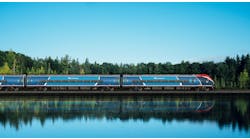

Trax Light Rail

For more than a decade, UTA’s Trax light rail system has carried passengers throughout Salt Lake County. The Trax system currently has three lines:

- Red line

- Green line

- Blue Line

JRRSC

The rail maintenance components were constructed within the western half (approximately 120,000 square feet) of the structure. The existing facility was also modified to include rail car service platforms and pits, machine room, parts storage and other amenities and can accommodate both high floor and low floor vehicles. With full build out, approximately 100 vehicles can be stored and maintained at the facility.

Storage of light rail vehicles is contained within the existing 24-acre property site. Yard improvements included grading and the addition of storage tracks, installation of an overhead catenary system (including power supply and signaling), and a connection to the West Valley light rail line. Through this connection to the West Valley light rail line, all of the vehicles used for the Trax system can easily be moved to the Jordan River Service Facility for maintenance.

The facility originally had more than 100,000 square feet of mezzanine space, much of which is now offices for UTA employees.

There are four pits constructed at the facility for use in maintenance and repair of Trax vehicles. The facility also includes a Macton Drop table, used for removing the traction power wheel assembly. The facility also has a complete truck set repair facility.

The JRRSC yard boasts a Siemens 3.0MW traction power substation that powers the yard and can also be used to power the shop-OCS in an emergency. A 0.5MW substation is used to power the OCS in the shop.

JRRSC has seven sets of tracks that come through the shop area, using bi-fold doors at each end, to allow the Trax vehicles to be repaired in an indoor facility. Currently there are two fully functional shops at the JRRSC: Coupler and Pantograph. Each of the two shops occupy about 4,000 square feet of space. An additional smaller shop for Ramps is also available. Planned shops include HVAC, Power Supply and Brakes.

Siemens S-70 light rail vehicles are used on the Trax lines and the majority of the train equipment is located on the roof; the upper mezzanine in the facility allows easy access to all of the equipment.

UTA Trax Facts

Vehicles

- Fleet: 77 Siemens S70 (low-floor), 17 Siemens SD160 (high-floor), 23 Siemens SD100 (high-floor)

- Capacity: 64 seats per LRV

- Crush Capacity: 184 per LRV, 736 per 4-car LRV

- Disability Access: 4 bridgeplates per LRV

- Consist: Up to 4 cars

Strutures/Facilities

- Total Stations: 57 including the S-Line Streetcar

- Total Track Miles: 44.8

- Square Feet Shop Space: 280,000

- Grade Crossings: 165

Personnel

- General Manager Staff: 16

- Operations Staff: 170

- Vehicle Maintenance Staff: 106

- Maintenance of Way Staff: 115

- Total Personnel: 407

Power Supply

- Power Distribution, Incoming: 12,500 AC

- Power Distribution, at Wire: 750 DC

- Number of Substations in System: 51

- Miles of Overhead Catenary: 103