When most people think about transportation in Los Angeles, they picture overcrowded freeways with vehicles of every size, shape, model and vintage barely moving in extended rush-hour traffic. While that image may be accurate enough, Los Angeles County is working diligently to create a world-class public transportation system, integrating new technologies to achieve better service and a lower carbon footprint.

In the next 25 years, Los Angeles’ changing demographics and expected growth and climate changes will require the county to significantly increase its public transportation capacity while also reducing pollution from current levels, a difficult task. In fact, Los Angeles County has long been at the forefront of adopting stricter regulations, emission controls and new technologies to combat toxic environmental pollutants and greenhouse gases. For the county’s Metro commuter rail line, this vision includes the incorporation of innovative systems and technologies that will affect a greener and sustainable transportation system.

To help fund this initiative, in 2009 Los Angeles County Metropolitan Transportation Authority received $4.5 million in federal stimulus funds through the Federal Transportation Authority (FTA) to install a wayside energy storage substation (WESS) at its Westlake/MacArthur Park Metro Red Line station. In the winning proposal, Ram Krishna, P.E., newly retired director of Project Engineering Systems for the Los Angeles County Metropolitan Transit Authority (LACMTA), detailed the various benefits of installing a WESS in a traction power application. To obtain the myriad of technical data needed to present his case, Krishna was assisted by his LACMTA staff in cooperation with Vycon Inc., a California-based flywheel energy storage manufacturer, and Turner Engineering, a U.S. consulting firm specializing in rail traction power.

Insert photo

Ram Krishna poses by an LA Metro commuter train

Krishna, now a consultant for his firm, Ram K Design and Construction Co., advocates building a technology solution that can store energy and put it to good use. In fact, during his tenure at LACTMA, Krishna helped the membership of the American Public Transportation Association (APTA) understand the advantages of energy storage and helped create the APTA Energy Storage Consortium. This consortium is now taking the lead for the rail industry in monitoring the progress of energy storage companies and any installations that may be accomplished in the United States.

Energy storage technologies applied to rail systems, said Krishna, “will improve the environment, save power costs, support utility company’s peak power demands and lower capital costs in new construction. Most transit traction power systems in the United States are missing an opportunity to save valuable energy.”

LACMTA is one of 43 transit agencies that will benefit from the $100 million U.S. Department of Transportation (USDOT) grant for cutting-edge environmental technologies to reduce global warming, lessen America's dependence on foreign oil and create green jobs.

Capturing and Storing Energy

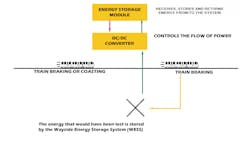

The WESS system will be a flywheel-based energy storage system, which captures the energy regenerated by trains as they brake into passenger stations. (Figure 1). In effect, the train propulsion motors are run in reverse to slow down and stop the train; therefore, these motors become generators, producing free energy using the train’s own inertia. Once this energy is captured, the WESS can store it until a peak load or strong energy demand is required. The maximum benefit is achieved by reducing the next peak power demand, which is typically the same train leaving the passenger station a few minutes later. By capturing and reusing this wasted energy, LACMTA can reduce its total energy consumption and peak power demand from the utility. The reduction of peak-power demand from these rail power systems is also a significant benefit for utility companies in Los Angeles, as demand can exceed supply during peak-usage periods, such as rush-hour afternoons and hot summer days. In addition, this process of energy demand reduction helps to reduce CO2 emissions — an ongoing goal in Los Angeles County.

Insert Figure 1.

Diagram of a Transit Traction Power System

In the United States and around the world, new electrically propelled subway rail trains and light rail vehicles (LRVs) use AC propulsion with induction traction motors and variable voltage as well as variable frequency drives. Benefits of these AC trains over older trains include higher performance, reduced starting energy use, regenerated braking energy, lower maintenance, and a broadened range of operating conditions. However, transit operators have found that without an energy storage system available to capture the regenerated power, AC trains and earlier DC chopper trains have not fully delivered their potential economic benefits. Therefore, transit operators are highly interested in finding an energy storage solution to capture the full energy savings benefit of regenerative braking. They know that such a solution also reduces the peak power usage that incurs high-peak power demand charges.

A WESS can also mitigate voltage sag and drop problems that most U.S. transit agencies experience in several sections of their existing tracks. Voltage sag results from physical limitations of the traction power supply, including substation location, rating and loads. Older traction power infrastructure can become limited by the addition of newer fleets or rail cars with higher power demand as well as by increased ridership, which either reduces headway times or adds cars to the existing trains. The current solution for this problem is the addition of a new traction power substation. “Transit operators have limited capital budgets for traction power improvements to resolve these problems,” noted Krishna. “Fortunately, an effective energy storage system can resolve voltage sag problems by supporting the grid voltage during a sag occurrence, yet can also switch to its energy-saving mode during other periods of the day. The double benefit of a WESS in these situations is a clear example of improving our rail systems with the future in mind.” Figure 2 shows a line diagram of a wayside energy storage system (WESS).

Insert Figure 2 Line Diagram of a Waysdide Energy Storage System (WESS)

Reduction of Total Energy Consumption

Each time a train brakes and stops, it generates energy that often goes unused due to the lack of an effective energy storage device in the system. The result is wasted energy, typically converted into heat and dissipated into the air. If we consider the amount of energy wasted per station over the next 20 years and the environmental effects of using utility power where regenerated energy could have been used, there is no question that energy storage must be a key component of every rail transit system.

To reduce total energy consumption, the WESS must capture and efficiently enable reuse of all of the energy regenerated by trains during braking. These savings directly reduce a transit operator’s electric costs. In the upcoming demonstration project in LA, testing is expected to show that the addition of the WESS will reduce energy consumption by up to 48 percent, a significant number which has a major impact on utility costs and environmental advantages. The proposal submitted to the FTA by the LACMTA detailed the direct impact on cost to the agency by analyzing the current utility billing format. By taking this energy recycling concept and applying it to each of the 200 stations in the LACMTA lines, we can see that the savings in energy costs and improvement in energy availability are critical for a growing and sustainable modern transportation system.

Reducing Peak Power Demand Charges

Krishna emphasized that to be fully effective, the WESS must also have the power capacity to peak-shave the high power demands required to accelerate trains from passenger stations. These peak power loads can often require up to 6 mega watts of power for only a few seconds at unscheduled times and can place a burden on the utility. Therefore, utility charges typically include costly peak power demand surcharges, which are determined by the time period(s) with the highest energy usage. Each electric utility sets a time period for measuring power usage; typically, it is one or two intervals of 5, 15 or 30 minute durations. Peak power demand charges are set by the period with the highest energy usage in a billing cycle, which is typically one month. Power demand charges during peak hours of the peak season can be as much as five times higher than charges during base periods. The peak power demand is calculated by dividing the energy used in the peak period by the duration. The units are kWh/h, or just kW. “Some transit operators report that their utility bills are difficult to understand based on the various surcharges and demand charges. But it is often the case that the peak power demand costs are higher than their total energy use costs,” noted Krishna.

Insert Table 1 – ESS Techology Comparison

Energy Storage Technologies

In looking for the optimum clean energy storage solution for LACMTA, Krishna concluded that flywheel systems would be the best solution. Table 1 compares the flywheel, supercap and battery technologies. The most effective technology for this application will require the ability to cycle (charge and discharge) up to once every 2 minutes while maintaining its capacity to absorb all of the regenerated energy created by a train. In the case of the LACMTA Westlake station, current requirements will require more than 100,000 cycles per year and over the next 10 years this number is expected to increase by 25 percent. “The flywheel is an attractive technology, as it is most efficient for high-power discharges in short bursts of approximately 15 to 30 seconds. This fits nicely into the required output of the traction power application. The flywheel is also impervious to cycle life and can, therefore, cycle indefinitely without wear and with high reliability,” said Krishna.

The problem with most existing energy storage technologies is that they have a limited life, dependent on the number of charge-discharge cycles they must produce. Most technologies are also temperature sensitive and require heavy maintenance. Chemical batteries, such as the familiar lead-acid batteries, have long been the accepted method to store energy in most applications. However, if a battery system must charge and discharge for each train arriving and leaving a passenger station over a full day and over an entire year, the life of the batteries is severely reduced. One idea is to increase the energy capacity of the battery system so that discharges are only partial and, therefore, their useful life is extended. The difficulty here is that there is an increase in the number of batteries, resulting in an increase in initial cost, increased maintenance and added reliability problems. The recharge time required in this application, which is 15 to 30 seconds to absorb the regenerated energy, is also much too fast for traditional batteries to absorb. A WESS demonstration site is in operation in Sacramento, Calif. This site supports voltage fluctuations on the light rail system using lead-acid batteries. The site has shown the benefit of a WESS in eliminating the voltage sag problem, but has also shown that lead-acid batteries cannot charge using the short duration, high-power input of the train’s regenerative energy.

Supercapacitor or ultracapacitor technology is also an option for this application. Although great strides have been achieved in lowering cost and improving cycle life of supercapacitors, they have not yet shown that they can support the 20-year life expectancy and harsh environment of the traction power application.

The next step is to install and demonstrate the flywheel technology in a traction power application. Based on existing data from flywheels used in critical back-up power applications and Vycon’s experience with installations in heavy cycling shipyard mobile cranes, Krishna believes that the flywheel can provide the benefit of high cycling without degradation and long life with high reliability and minimal maintenance.

Although busy with his new consulting firm, Krishna keeps in close contact with his former LACMTA colleagues. He expects that the wayside energy storage substation will be in operation by June 2012. He hopes that the results of his dedicated effort will convince other transit operators and communities to follow his lead and help improve the efficiency of our power grids. Can we afford to throw away free energy over the next 50 years? Krishna says emphatically, “No!”

P.J. Jennings is president/CEO of Jennings & Associates Communications Inc., Carlsbad, Calif.